Liquid ring pump LR, LRM

Characteristic:

- oil-free operation

- they are suitable for suction of gases and vapors

- they can reach relatively deep vacuum

- they are able to work simultaneously

with the gas and liquid

- anti cavitation protection is ensured by

installation of anti-cavitation valve

- safe operation with minimal maintenance

- smooth running without vibration

- economic operation

Applications:

- Chemical industry

- Food industry

- Pharmaceutical industry

- Paper Industry

- Packaging industry

- Evaporation and drying

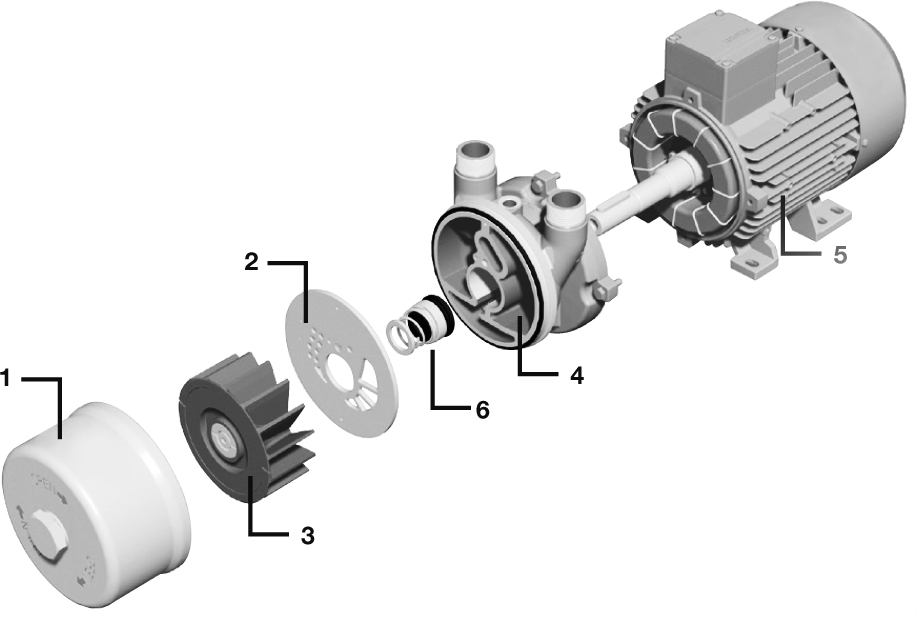

Principle:

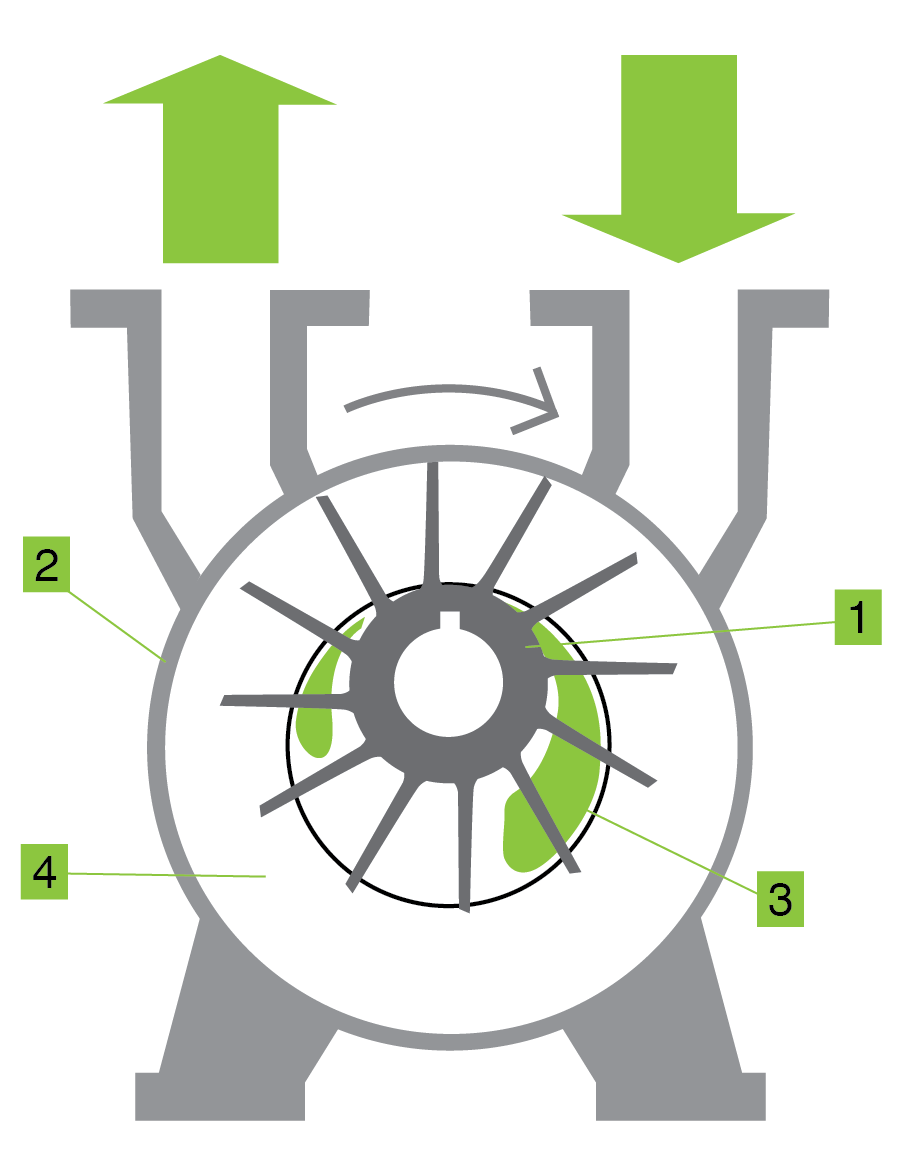

Rotor with fixed blades (1) is rotating in the stator (2), in which is situated eccentrically. Water ring is created from the service liquid (3) by the centrifugal force. The vacuum is formed and the pressure is changed in the compression chambers (4) between the blades and water ring. During the operation, the pump has to be supplied by adequate quantity of service liquid to achieve desired performance. Service liquid is also very useful for cooling of the liquid ring vacuum pump and for receiving possible contamination of sucked gas.

| Type | Fre- quency (Hz) |

Suction (m3/h) |

Vacuum (mbar) |

Motor (IP54), 50Hz, 60Hz |

Sound (dB) |

Weight (kg) |

Oper.liquid qty. (m3/h) |

Recommended type of |

||

| Output | Rated voltage | Rated current | ||||||||

| (kW) | (V) | (A) | ||||||||

| Three phases | ||||||||||

| LR 060-H06 |

50 | 28 | 33 | 0,75 | 200-240 Δ/345-415 Y |

4,6 ∆/ 2,5 Y | 62 | 17 |

0,20 |

R-1/R |

| 60 | 32 | 1,1 | 200-240 Δ/345-415 Y | 5,2 ∆/ 3,1 Y | 67 | |||||

| LR 061-H16 | 50 | 48 | 33 | 1,5 | 200-240 Δ/345-415 Y | 7,5 ∆/ 4,3 Y | 65 | 22 | 0,23 | R-1/R |

| 60 | 53 | 2,2 | 200-240 Δ/345-415 Y |

9,2 ∆/ 4,6 Y | 69 | |||||

| Type | Fre- quency (Hz) |

Engine speed RPM |

Suction |

Vacuum (mbar) (abs) |

Motor (IP54), 50Hz, (60Hz)* |

Sound pressure level (dB) |

Weight (kg) |

Max. operating liquid at continuous operation (l/h) |

Max. operating liquid at intermittent operation (l/h) |

Recommended type of |

||

| Output | Rated voltage | Rated current | ||||||||||

| (kW) | (V) | (A) | ||||||||||

| Three phases | ||||||||||||

| LRM 25 |

50 | 2850 | 25 | 33 | 0,75 | 345-415 Y | 1,76 Y | 68 | 18 | 500 | 600 | R-2/R |

| LRM 50 |

50 | 2850 | 45 | 33 | 1,5 | 345-415 Y | 3,13 Y | 68 | 23 |

600 | 720 | R-2/R |

| LRM 95 |

50 | 1450 | 75 | 33 | 2,2 | 345-415 Y | 4,83 Y | 65 | 56 | 1700 | 2000 | R/3 |

| LRM 130 |

50 | 1450 | 120 | 33 | 4,0 | 345-415 Δ | 8,15 ∆ | 65 | 73 | 1800 | 2200 | R/3 |

| LRM 255 |

50 | 1450 | 180 | 33 | 5,5 | 345-415 Δ | 11,0 ∆ | 65 | 100 | 3000 | 3600 | R/3 |

| LRM 325 |

50 | 1450 | 300 | 33 | 7,5 | 345-415 Δ | 15,0 ∆ | 72 | 132 | 3200 | 3900 | R/3 |

| LRM 455 |

50 | 1450 | 400 | 33 | 11,0 | 345-415 Δ | 21,2 ∆ | 72 | 205 | 3800 | 4600 | R/4 |

|

Vacuum pumps Rotary vane RV, Piston pumps VP, Liquid ring pump LRDatasheets (pdf/3MB)

Liquid ring pump LROperating instructions (pdf/2MB)

|

|

|||||||||||||

Possibility of material design in AISI for models LRM 25 - LRM 455 |