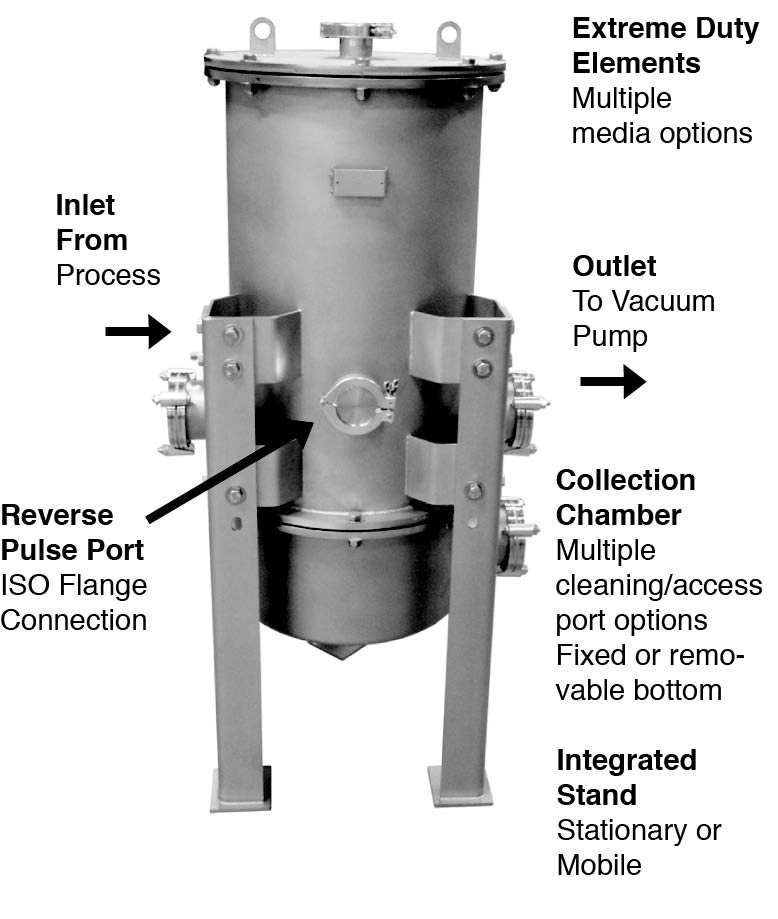

Extreme Filtration with Reverse Pulse Technology

|

Filtrers / Reference OnlyPart Number w /PTFE Element |

Material of construction |

Inlet & Outlet |

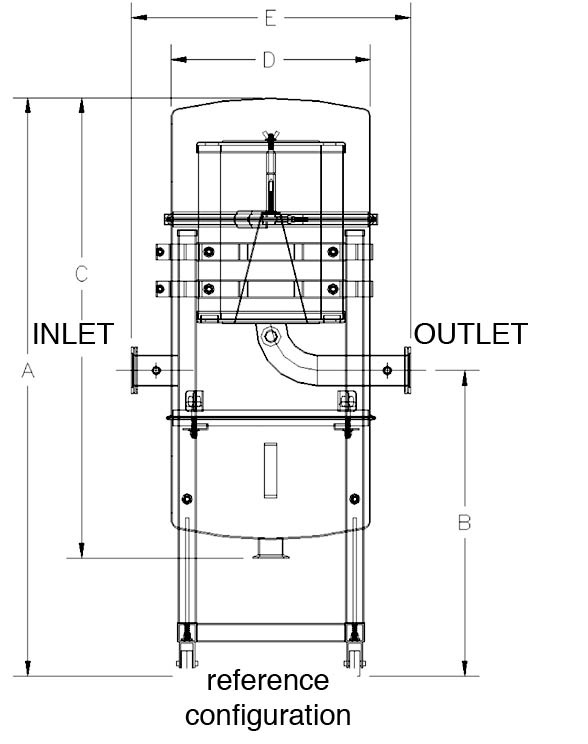

Reference only dimensions (mm) | ||||

| A | B | C | D | E | |||

| SP-TF235Q-400 | Carbon Steel | 4” FLG | 1098 | 657 | 857 | 305 | 514 |

| SP-TF235Q-400F | Stainless Steel | 4” FLG | 1098 | 657 | 857 | 305 | 514 |

| SP-TF375Q-100 | Carbon Steel | ISO K 100 | 1184 | 625 | 943 | 406 | 584 |

| SP-TF375Q-100S | Stainless Steel | ISO K 100 | 1184 | 625 | 943 | 406 | 584 |

| SP-TF375Q-160K | Carbon Steel | ISO K 160 | 1184 | 625 | 943 | 406 | 587 |

| SP-TF375Q-160S | Stainless Steel | ISO K 160 | 1184 | 625 | 943 | 406 | 587 |

|

|

Characteristic:

> Integrated reverse pulse technology unloads and extends filter

life improving maintenance intervals and process run time

> PTFE Media: 99% efficiency @ 0.3 micron - Temp (continuous): 275 °F(135 °C)

> Dutch twill media: 99.5% efficiency @ 1 micron - Temp (continuous): 350 °F(176 °C)

> Interchangeable filter element provides for easy replacement

> Integrated support stand with guides simplifies maintenance

> Available in carbon steel or all stainless steel construction

> Large holding capacity extends maintenance intervals

> High conductance design

> Leak rate: Minimum standard of 1x10-7 mbar L

Applications:

> Crystal growing furnaces

> Vacuum coating and lamination

> Wet & dry vacuum pumps & systems

> Compatible with most dopants

> Safeguard pumps from harmful particles (SiOx)

> Prevent particles from contaminating pump oil

> Reduce risk of backstreaming

> Prevents build up and seizing in dry pumps