Tube diffusers

Tube diffusers

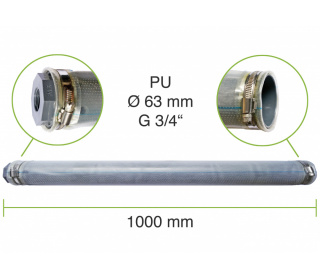

Tube diffuser - compact and universal due to its high oxygenation efficiency and long lifetime in the aeration process.

- floating element flooded, ¾ ”threaded head

- PVC or polypropylene (PP) support tube

- external diameter 63 mm

- air is guided between the membrane and the support tube

- typical installation depth is 6 - 7 m

A = membrane, B = the steinless steel clamp, C = the supporting pipe, D = EPDM sealing

Tube diffuser - applications:

- building of the new water treatment plants

- reconstruction and intensification of the existing water treatments plants

- intensification of the fish ponds

- aeration of the water streams and pools

- mixture of the galvanic baths and the neutralization pools

- agitation of the suspenses

- biodegradation of the oil sludges, biotechnology...

Benefits of the tube diffuser:

- regular and continuous bubble production all over whole diffuser length

- no liquid is leaking in after operation stop or diffuser choking

- minimal pressure lost

- optimized shape, density and size of perforation

- high rigidity

- long lifetime (in common wastewater up to 12 years)

- optimal wall thickness ensuring high mechanical endurance

- excellent chemical resistance

Aeration elementsDisc diffusers, Tube diffusers, Aeration membrane (pdf/626kB)

We supply tube diffusers with PU membrane and tube diffusers with EPDM membrane:

Types of tube diffusers |

|

| Tube diffuser with EPDM membrane |

Tube diffuser with polyurethane membrane |

| the EPDM membrane | The polyurethane membrane |

| the air temperature at the outlet must not exceed 80 °C | the air temperature at the outlet must not exceed 70 °C |

|

|