Turboblowers

|

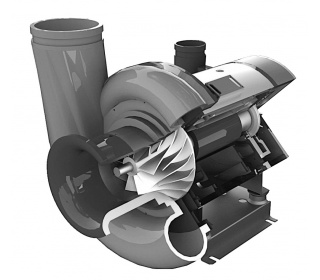

IN-ECO is a distributor of high performance turboblowers incorporating the latest innovations in air bearing, precision impeller machining, high speed, high efficiency permanent magnet motor, high speed control frequency converter, automatic control logic and system design.

The turbochargers received a certificate with the CE mark, which comply with the legal regulations of the European Union. It was awarded the ISO 9001 certificate, which indicates product quality, as well as the ISO 14001 certificate, the subject of which is the promotion of environmental protection and pollution prevention. All devices are labeled „High efficiency appliance,“ certifying them as highly efficient.

|

.... |

|

Enegry saving |

Low maintenance costs |

|

– saves up to 45% of energy relative to comparable blowers

|

– non-lubricating air-foil bearings |

No vibration |

Compact dimensions |

|

– magnetic levitation shaft allows a vibration-free operation |

– the size of our Turbo Blower machine is only one third of PD Blower |

Highly efficient, high speed motor with a permanent magnet (PMSM)

PMSM motors are optimized for high-speed rotation; minimizing current loss and delivering a maximum efficiency of 98%.

Cooling system

Completely self-cooling system that cools the motor with the sucked outer ambient air by rotating the cooling fan. Our cooling system does not require a separate power source, unlike the water-cooled type which requires a complex cooling water circulation system (including a pump). No maintennce required, including cooling water replenishment and pump management etc.

Turboblower air bearing

Non-contact air bearing supports the load of the rotating body by leveraging the compression via the wedge effect around the shaft rotating at a high speed. Our air bearings are 100% lubricant-free, contactless, and eco-friendly. No maintenance needed due to proprietary non-lubricant system. Special coating reduces frictional wear between the rotor and bearing, providing a stable and long service life.

High-efficiency inverter optimized for high-speed rotation motor

- 0.3% Unload Power Consumption

- Smaller motor start-up current required compared to other inverters

- Smaller noise generation, electronic noise suppression

- Precise operation and smooth start

- High efficiency and reliability with 96% or more control efficiency

- Fast reaction rate even with sudden load fluctuations

- KEB (Kinetic Energy Back-up) function that can decelerate and stop quickly and safely in case of power failure

- Sensor-less technology prevents malfunctions at high temperatures

- Less than 1% starting current- No need of a separate startup control panel

User-friendly control system

Real-time monitoring of the information of the blower operation such as flow rate, pressure, temperature, and rotation speed through the LCD display

- Touchscreen display allows for easy operations

- Enhanced user convenience with multi-language support

- Optimized control logic for high-speed blower allows control operation according to various user’s needs in different modes such as constant pressure, constant flow rate, and constant speed

- Realization of remote control by Modbus RTU protocol support via RS485 serial port

- Reduces the possibility of surge that can occur during operation of the blower through surge prevention control logic

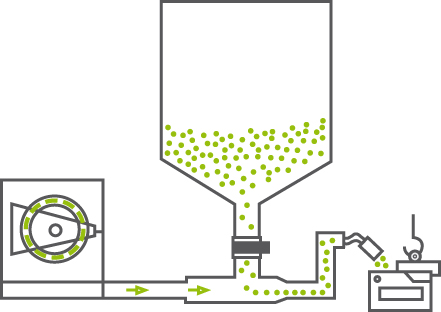

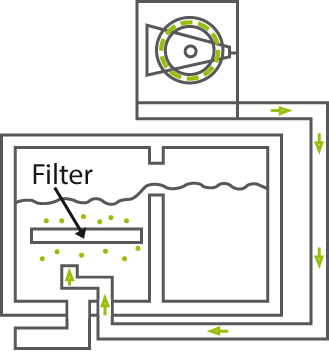

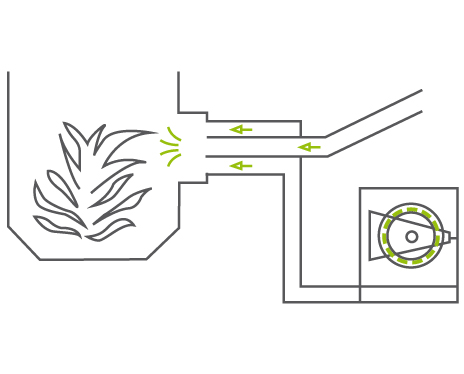

Application

Turboblowers have a wide range of uses in industry. They can be used as a source for high-quality sandblasting of large areas, for plating, for burning, for countercurrent cleaning of filters. They are an important part of large water treatment plants where compressed air supply is required. In industry, they are used for segmentation of materials, in aquariums and in other industries.

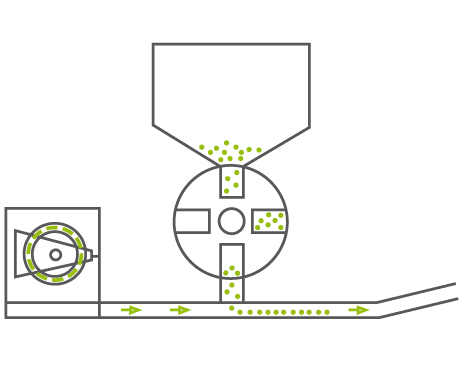

Sandblasting

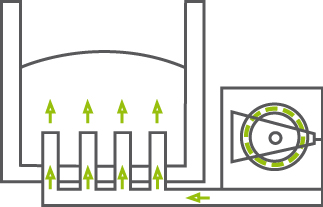

Countercurrent filter cleaning

Incinerators

Composting, fermentation

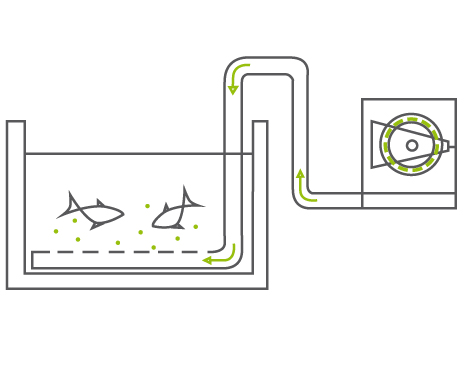

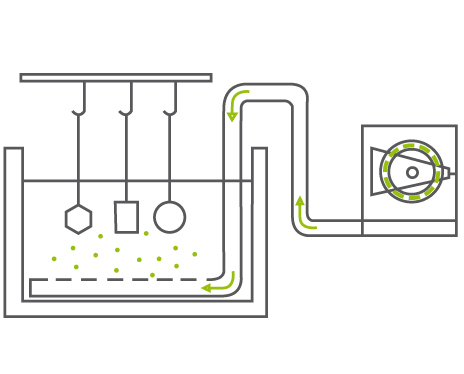

Aeration, oxygenation

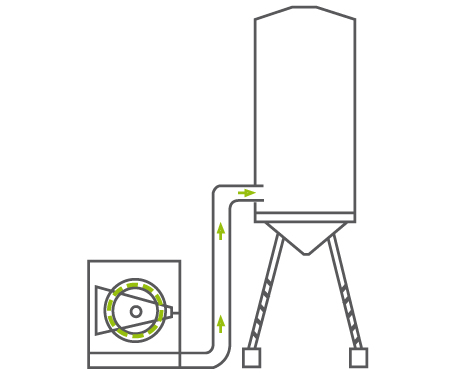

Dehumidification, drying

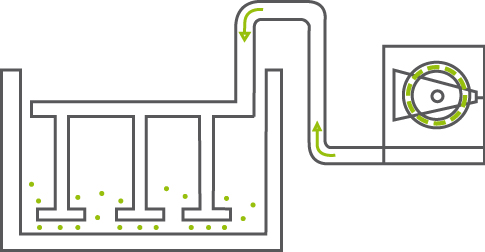

Wastewater treatment plants

Segmentation of materials

Galvanization

| Model Name |

Flow (m3/min) |

Pressure

(bar) |

Size (mm) | Shaft Power (HP) |

Discharge (A KS 10K) |

||

| L | W | H | |||||

| (mm) | (mm) | (mm) | |||||

|

Turboblowers |

|||||||

| TB 10 | 3~8 | 0.3~0.8 | 1200 | 700 | 1120 | 10 | 150 |

| TB 15 | 5~13 | 0.3~0.8 | 1200 | 700 | 1120 | 15 | 150 |

| TB 20 | 6~15 | 0.3~0.8 | 1200 | 700 | 1120 | 20 | 150 |

| TB 30 | 7~25 | 0.3~0.8 | 1200 | 700 | 1120 | 30 | 150 |

| TB 50 |

10~42 |

0.3~0.8 | 1200 | 700 | 1120 | 50 | 150 |

| TB 75 | 18~62 | 0.3~1.0 | 1400 | 850 | 1425 |

75 |

200 |

| TB 100 | 23~105 | 0.3~1.0 | 1400 | 850 | 1425 | 100 | 200 |

| TB 125 | 25~115 | 0.3~0.8 | 1400 | 850 | 1425 | 125 | 200 |

| TB 150 | 28~130 | 0.3~1.0 | 2050 | 1033 | 1697 | 150 | 300 |

| TB 200 | 36~210 | 0.3~1.0 | 2050 | 1033 | 1697 | 200 | 300 |

| TB 250 | 40~235 | 0.3~1.0 | 2050 | 1033 | 1697 | 250 | 300 |

| TB 300 | 80~260 | 0.3~1.0 | 2260 | 1263 | 2187 | 300 | 400 |

| TB 400 | 80~275 | 0.3~1.0 | 2260 | 1760 | 2187 | 400 | 400 |

| TB 500 | 90~330 | 0.6~1.0 | 2260 | 1760 | 2187 | 500 | 500 |

| TB 600 | 100~420 | 0.6~1.0 | 3600 | 2150 | 2187 | 600 | 500 |

| TB 800 | 100~520 | 0.6~1.0 | 3500 | 2150 | 2187 | 800 | 600 |

| TC 100 | 10~30 | 1.2~2.0 | 1690 | 1033 | 1425 | 100 | 150 |

| TC 150 | 12~51 | 1.2~2.0 | 2050 | 1033 | 1697 | 150 | 200 |

| TC 200 | 12~51 | 1.2~2.0 | 2050 | 1033 | 1697 | 200 | 250 |

| TC 300 | 20~85 | 1.2~2.0 | 2260 | 1263 | 2187 | 300 | 250 |